pla impact testing|hard pla impact strength : supermarket The impact test is used to determine the sensitivity to cracking of polymer . WEBModal title. OK. Confirma.

{plog:ftitle_list}

Apenas obedeci, fiz, já era madrugada, em torno de uma da manhã. Eu como ela e ela como eu, papéis invertidos, virei a esposa e ela o marido. Arriscamos sair daquela .

pla vs pla filament

To address this issue, the current research aims to characterize PLA utilizing standard ISO 179-1:2010 while varying printing parameters such as infill density, and printing speed. This investigation focuses on how the afore mentioned properties affect the resulting .The impact test is used to determine the sensitivity to cracking of polymer .

pla maximum impact strength

Hence, in this study, the impact strength of the FFF fabricated PLA has been .

In this study, the Taguchi experimental method was designed and applied to evaluate the effect of print parameters such as infill density (%), raster angle (°), layer height .

The impact test is used to determine the sensitivity to cracking of polymer materials as well as the impact strength. The Zwick Roell device was used for impact testing .

In this study, the Taguchi methodology was used to investigate the effects of Fused Deposition Modeling (FDM) production parameters tensile strength, three-point bending .

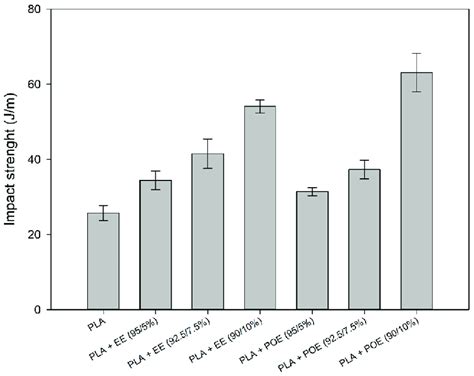

Regarding the impact strength, PLA displays a value of 22 J m −1, another demonstration of its inherent fragility, whereas PCL does not break under the testing conditions employed in this work. The impact strength of . The optimized parameter set obtained through the Taguchi method, namely, a 100% infill density, 45/−45 raster angle, 0.25 mm layer height, and 75 mm/s print speed, enhances the impact strength .

The results of the present study show that LAK301 acts as a very efficient nucle-ating agent by increasing crystallinity percentage from 5.6% in pure PLA to 12% in PLA/LAK301 5%wt/206 3NL, and .

pla filament tensile strength

Comparing Impact Resistance of 21 Filaments for 3D Printing.: Hi everyone. I built a simple testing bench to compare the impact resistance of various filaments, including PLA, PETG, ABS, ASA, HIPS, PC, Nylon, PP, TPU and PLA+. Technical data sheets exist for most filaments, but data is rarely directly comparab. In order to test this, I performed an impact test with notched IZOD specimens. In this apparatus the coupons are placed in a vice and then struck by a hammer. . Impact resistance was the lowest for PLA, next came PETG and ASA was by far the most tough material. Under elevated temperatures, PLA failed at first, PETG seems to be usable up to . The impact test was essentially carried out in order to get a general outlook on the material's toughness by measuring the amount of energy required to break a specimen completely. . Based on the fatigue test, 7 wt. % kenaf/PLA are the most suitable to act as an AFO material because it has the longest fatigue life and good load-carrying . The best formulation, with the addition of EJ-400, guarantees a useful compromise in terms of mechanical properties providing the highest value of Charpy impact resistance (9.1 kJ/m 2), a good value of elongation at break (around 8%) and an acceptable decrement of the Elastic Modulus with respect to pure PLA and binary blends, making this .

PLA vs. PETG vs. ABSBirdbone Helium frame impact testing(short edit)Results confirm typical datasheet impact strength results, which show ABS has 10x greater. Hence, in this study, the impact strength of the FFF fabricated PLA has been evaluated as a function of three build variables viz. raster angle, layer height, and raster width. The impact test specimen was fabricated at varying build conditions and tested as per the ASTM D256 standard. Results showed that the raster angle was found to be the .High Impact PLA Patented Nanotechnology. Buy 5 for .99 each, Buy 3 for .49 each Free Shipping on Orders over (contiguous US only) . This analysis was conducted using Notched Izod Impact Strength testing (ASTM D256). VO3D PLA filaments are manufactured in the US to the highest quality standards and currently come in eight colors.

Overview of the fracture surface of composites with a mass proportion of 10% after impact testing: (a) PLA/Cordenka composite, (b) PLA/flax composite. Download: Download full-size image; Fig. 2. Detailed pictures of the fracture surface of composites with a mass proportion of 30% after impact testing: (a) PLA/Cordenka composite, (b) PLA/flax .

The other materials pretty much failed in the order we expected. PLA was the first to break, and when it broke, it shattered. PETG also failed violently, but was quite a bit stronger than PLA. This is why it’s an excellent general purpose filament - it’s stronger than PLA and much easier to print than ABS.

These improvements can provide 3D printed parts with increased flexibility, rigidity, and impact resistance compared to regular PLA. However, it cannot reach the conclusion that PLA+ is definitely better than standard PLA. . Using samples of Anycubic's PLA and PLA+ for flexural strength testing, the PLA showed a result of 83MPa, while the .Check out our *CNC Kitchen products* at https://cnckitchen.store/ or at our global resellers https://www.cnckitchen.com/resellerPLA is still the most common . Test #4: Impact test. And the last test was devoted to checking the impact strength. Polymaker says PolyMax PLA should have roughly the same toughness as ABS. Since we do not have specialized equipment for . Regular PLA is really easy to print and stronger than some might expect, though if a PLA part actually fails, it shatters quite violently. During the last years, many companies brought modified PLA filaments onto the market .

Consistent with the morphology results obtained via SEM and the mechanical properties obtained via tensile/impact testing, the influence of pectin dispersion in the PLA matrix plays an important . Before we get to the impact test, let’s take a look at the stiffness of the foaming PLA that I tested using a 3-point-bending test. This might be a property that is important for you if you are designing your plane for example, so that the wings don’t flex too much. . The horizontal specimens again behaved similarly to the static tests .

The tensile testing of PLA composites was carried out according to the ISO 527-2 standard at 23 °C using an Instron 5566 (Instron, Norwood, MA, USA) universal testing machine at 5 mm/min cross-head speed and 115 mm gauge length. . Instrumented impact testing offers more detailed information about the two steps of fracture, crack initiation . The main goal of this study is the comparison of different reinforcement architectures on the low-velocity impact behavior of green composites. The study includes the comparison of unidirectional, basket weave, and twill weave flax/PLA composites, they are subjected to unidirectional tensile tests, drop-weight impact tests, and after-impact . In addition, the 3D-printed thermochromic PLA specimens were subjected to testing to further confirm that material properties have a significant impact on the mechanical and thermal responses, including softening, hysteresis loop, and permanent set. This information is valuable for optimizing the performance of these structures and developing .Ultimaker PLA Technical data sheet 1 Ultimaker PLA Technical data sheet General overview . Charpy impact strength (at 23 °C) ISO 179-1 / 1eB (notched) . Test Method Typical value Melt mass-flow rate (MFR) ISO 1133 (210 °C, 2.16 kg) 6.1 g / 10 min

iphone drop test pop its

In our recent test run, the OVERTURE Tough PLA Plus performed admirably. We noticed the toughness of the filament almost immediately. It’s certainly made our project components much sturdier compared to when we used regular PLA filaments. . PLA+ filaments typically offer improved toughness and higher impact resistance compared to standard .

A couple of years ago, I read the first publication on the impact of PLA color on mechanical properties and just recently, another paper was released that did a similar investigation for PLA and ABS. Both showed a clear influence of color on strength, stiffness, impact resistance, and ductility, ranging up to a 30% difference in properties . The low humidity test showed that PLA samples had ‘nearly similar impact strengths.’ Samples also displayed high impact strength above the glass transition temperature (60⁰C).

Ireland, D. R. (1976) Critical review of instrumented impact testing, Conf on Dynamic Fracture Toughness, London, 47–61. Google Scholar Kalthoff, J. F., Winkler, S. and Böhme, W. (1985) A novel procedure for measuring the impact fracture toughness KId with precracked Charpy specimens, Journal de Physique, C5 No. 8, 279–286.

pla filament impact strength

I'd like to test more of these metrics (see Future Directions). As an example, Polymaker sells Polymax PLA which they claim has an impact resistance 2.3 times that of Polylight PLA Pro, however, they still recommend Polylight for 2A purposes because of .

pla 3 point bending strength

hard pla impact strength

24 de abr. de 1974 · 说到73,就不得不提上一年的72,经典之后的经典,前作自然是王为一的滑稽剧。在股票热炒的年代,政府简直就是个屁,通过香港街73号左邻右舍悲喜交加的缩影,73行各有苦虑,痛诉了现实社会的不堪入目,而人间仍然充满温暖!

pla impact testing|hard pla impact strength